How to Choose UV Ink: Understanding Hard, Neutral, and Soft Inks

In recent years, the use of UV flatbed printers in the industrial printing industry has become increasingly widespread and proficient. These devices cater to a variety of sectors and materials, including customized home decor, building materials, advertising, mobile accessories, signage, crafts, decorative paintings, and much more. With the rise in UV printers, the UV ink market has also expanded with a vast array of options. This article seeks to guide you on how to choose the right UV ink for your applications.

1. Choosing UV Ink Based on Performance

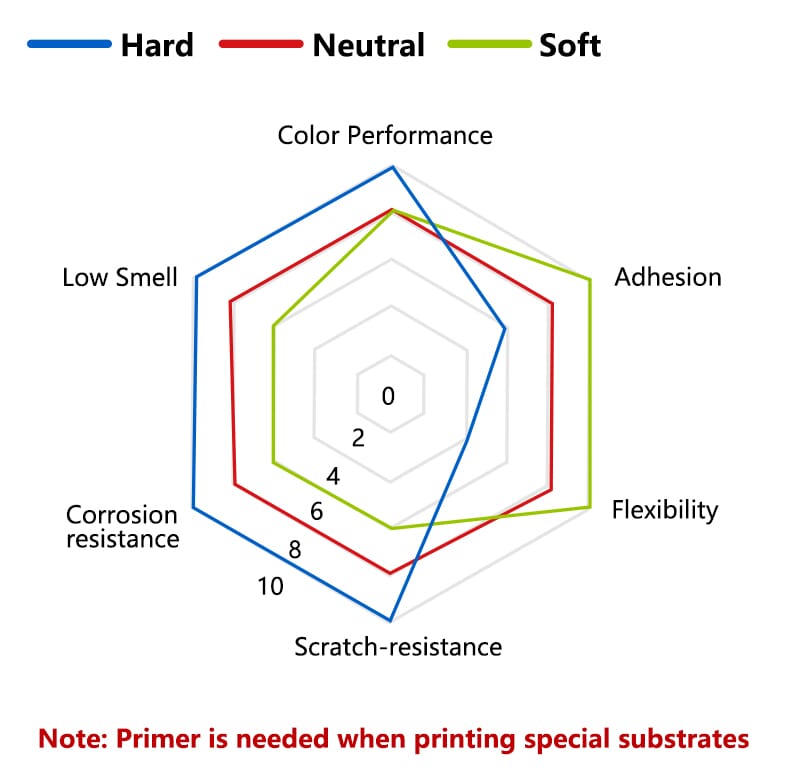

The more accurately you can identify the right ink for your needs, the easier it will be for manufacturers to use. UV inks are primarily classified into three categories: soft, neutral, and hard.

UV Soft Ink

Advantages: UV soft ink boasts excellent stretchability and bendability, good adhesion, and decent low-temperature resistance.

Disadvantages: The ink layer is overly soft, which can easily leave scratch marks when used on hard materials.

| UV Soft Ink | Specifications |

|---|---|

| Color | CMYKWLcLmV |

| Sunlight-proof grade | Lv.8 |

| Outdoor durability | >2 years |

| Rigidness | 5B |

| Room temperature stretchability | >160% |

| Low-temperature stretchability | >140% |

| Bent ink cracking temperature | <5℃ |

| Water Wipe Resistance Grade (Lv.0 means 100% resistance) | Lv.2 |

| Acid/Alkali/Alcohol Wipe Resistant Grade (Lv.0 means 100% resistance) | Lv.4 |

| Smell grade (Lv.0 means no smell at all) | right after printing: Lv.4, 24 hours after printing: Lv.1 |

| Applicable models | UV RTR Printers RB-1600 to RB-3200, UV Flatbed Printer from RB-4030 Pro to RB-2513 |

Applicable Materials: Illuminated cloth, soft film, wall cloth, wallpaper, car stickers, PVC film, PET light sheet, oil painting cloth, 3P cloth, and other soft materials.

UV Neutral Ink

Advantages: UV neutral ink adheres well to a variety of materials like plates and soft substances without the need for a coating. It has a certain scratch resistance ability.

Disadvantages: The hardness is somewhat lacking, making it unsuitable for high-hardness materials like glass.

| UV Neutral Ink | Specifications |

|---|---|

| Color | CMYKWLcLmV |

| Sunlight-proof grade | Lv.8 |

| Outdoor durability | >2 years |

| Rigidness | H |

| Room temperature stretchability | >140% |

| Low-temperature stretchability | >110% |

| Bent ink cracking temperature | <15℃ |

| Water Wipe Resistance Grade (Lv.0 means 100% resistance) | Lv.1 |

| Acid/Alkali/Alcohol Wipe Resistant Grade (Lv.0 means 100% resistance) | Lv.2-4 |

| Smell grade (Lv.0 means no smell at all) | right after printing: Lv.3.5, 24 hours after printing: Lv.1 |

| Applicable models | UV Flatbed Printer from RB-4030 Pro to RB-2513 |

Applicable Materials: Acrylic, PS board, PVC foam board, KT board, and so on.

UV Hard Ink

Advantages: UV hard ink has a high hardness ink layer, offers the best scratch resistance, and is resistant to weak acids and alkalis.

Disadvantages: It has the weakest stretchability and bendability performance.

| UV Hard Ink | Specifications |

|---|---|

| Color | CMYKWLcLmV |

| Sunlight-proof grade | Lv.8 |

| Outdoor durability | >2 years |

| Rigidness | 4H |

| Room temperature stretchability | — |

| Low-temperature stretchability | — |

| Bent ink cracking temperature | — |

| Water Wipe Resistance Grade (Lv.0 means 100% resistance) | Lv.1 |

| Acid/Alkali/Alcohol Wipe Resistant Grade (Lv.0 means 100% resistance) | Lv.1-2 |

| Smell grade (Lv.0 means no smell at all) | right after printing: Lv.3, 24 hours after printing: Lv.1 |

| Applicable models | UV Flatbed Printer from RB-4030 Pro to RB-2513 |

Applicable Materials: Glass, ceramic tiles, stainless steel, aluminum products, and other high-hardness materials.

2. Other Considerations When Choosing UV Ink

While the performance of the ink is critical, other factors should also be considered:

- Color Saturation: High-quality UV ink should produce vibrant, pure colors with high saturation.

- Adhesion: The UV ink should adhere well to the chosen substrate. If it peels or chips easily, it may not be the right choice.

- Sustainability: Check if the UV ink you’re considering is environmentally friendly. Some UV inks are made with volatile organic compounds (VOCs), which can be harmful to the environment.

- Curing Speed: UV inks should cure quickly under UV light, reducing the time it takes for prints to dry and speeding up production times.

- Price: Consider the cost of the UV ink. While cheaper inks might be tempting, they may not provide the performance or durability you need.

- Manufacturer and Supplier: It’s important to choose UV inks from reputable manufacturers and suppliers. They should provide excellent customer service and support, including guidance on how to use their inks most effectively. Rainbow Inkjet provides full UV printing solutions including quality ink, welcome to ask us to print a sample to verify the result.

3.All in All

Choosing the perfect UV ink is a process that requires understanding your specific needs, the material you’re working with, and the desired outcome of the print. Always remember to test the ink on a small batch of material before committing to a large order to ensure it meets all your expectations. And if you are interested in a full printing solution, please don’t hesitate to contact us and have a chat with our professionals.

-

Call us on:

Call us on:

+86-15821017843 -

Email Us:

Email Us:

info@rainbowdgt.com -

Jiurun Business Building, No.1658 Husong Road, Songjiang District, Shanghai, China

Jiurun Business Building, No.1658 Husong Road, Songjiang District, Shanghai, China - Privacy Policy

- Copyright © No.3, zone 4, yuliu old district, Guangming New District, Shenzhen,518132, China All Rights Reserved